Electro Galvanized Steel Process:

Electro galvanized sheet is a method in which zinc and the material to be plated are put into a solution and energized, so that the zinc dissolved in the solution is precipitated on the surface of the material to be plated.

There are many kinds of electro galvanized steel processes, such as zinc ammonium bath using acidic solution, zinc potassium chloride bath, cyanide bath and zincate bath using alkaline solution, etc.

The coating thickness of electro galvanized sheet is about 2~25µm.

The advantage of electro galvanized sheet is that the thickness of the coating is uniform and the decoration is good; the disadvantage is that chromate treatment is required to improve the corrosion resistance of electro galvanized steel and prevent white powder from being produced due to corrosion.

Electro-Galvanized Steel Properties:

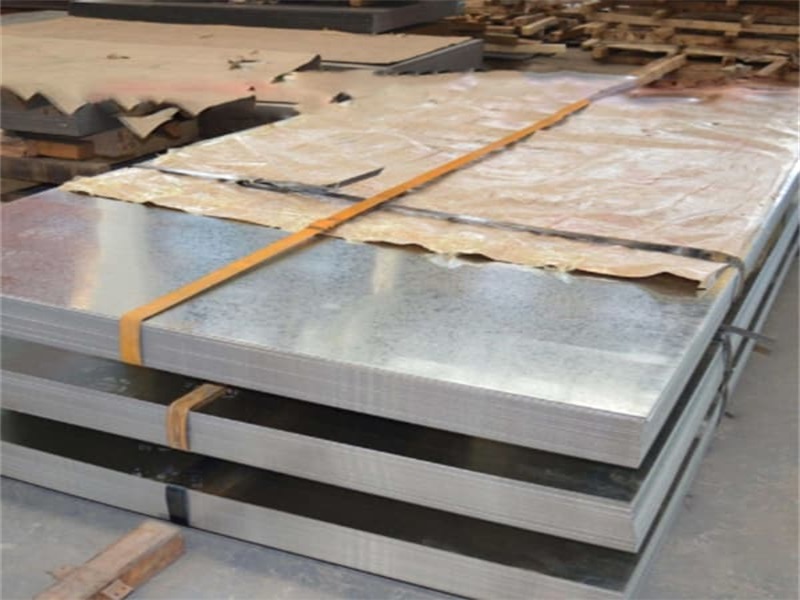

Electro galvanized steel is a steel plate that uses an electro-galvanized process.

The substrate before the electro galvanized steel process is a cold-rolled steel plate, which has excellent machinability, and because the thickness of the electro galvanized steel coating is uniform, it has a beautiful and glossy appearance, and the coating performance is excellent, and it can be made into various colors.

However, the electro galvanized layer is thinner than the hot dipped galvanized layer and has poor corrosion resistance, so it cannot be used in the open air and in places where it is easy to come into contact with water.

Application:

Specific applications of electro galvanized sheets:

1. Automotive: Body panels, radios, fans, air cleaners, filters, fuel tanks.

2. Household appliances: refrigerators, washing machines, dryers, air conditioners, VCRs, CD players, color TVs, tape recorders, microwave ovens, stereos.

3. Office machines: copiers, computer cases, printers, monitors, telex machines.

4. Construction: doors, wall partitions, studs.

5. Production machinery: agricultural machinery, industrial robots.

6. Clean industry: wall decoration in operating room.

7. Others: electrical distribution, oil storage tank, motor cover, steel furniture floor.

Order Process:

The order process of our Delong Metal Electro Galvanized Sheet products:

1. Receive Inquiry(drawing,temper,etc.)

2. Feasibility study & quotation

3. Offer is accepted by customer

4. Comfirmation on order details

5. Signing Pl

6. Receive deposit

7. Design&make the die for extrusion

8. Mold test,make samples

9. Sample approval,mass production

10. Receive balance

11. Deiivery

FAQ:

Q:Can you send samples?

A:Sample can be for free,freight cost collect.

Q:What product information do I need to provide?

A:Steel grade/thickness/width/quantity,these will decide the price.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001,CE,SGS,BV and other certifications.

Q:How about the delivery time?

A:Regularly the delivery time around 10-15 days,customized one will inform the delivery time ahead.

Q:Does the product have quality inspection before loading?

A:All the products are strictly tested before packaging,also can inspect by third party inspection.

Q:How to pack the products?

A:Standard export package with waterproof film and wooden pallet.It can effectively protect products from corrosion.

Back to top

Back to top

Free quotation

Free quotation

Online Service

Online Service

Scheme customization

Scheme customization

Return to bottom

Return to bottom