Standards:

-

GB: 12Cr17Mn6Ni5N/1Cr17Mn6Ni5N

-

ASTM: S20100/201

-

JIS: SUS201

-

ISO: X12CrMnN17-7-5

-

EN: X12CrMnN17-7-5/1.4372

Properties:

Chemical properties:

|

201 Stainless Steel Coil |

C |

≤0.15 |

|

Si |

≤1.00 |

|

|

Mn |

5.50-7.50 |

|

|

P |

≤0.050 |

|

|

S |

≤0.030 |

|

|

Ni |

3.50-5.50 |

|

|

Cr |

16.00-18.00 |

|

|

N |

0.05~0.25 |

Mechancal properties:

|

Cold Rolled 201 Stainless Steel Coil |

|

|

Tensile Strength |

520MPa |

|

Yield Strength |

275MPa |

|

Elongation |

55 to 60% |

|

Elastic Modulus |

29000000psi |

|

HRB |

≤100 |

Physical properties:

|

201 Stainless Steel |

|

|

Density/(kg/dm³)20℃ |

7.93 |

|

Melting Range/℃ |

1398~1453 |

|

Specific Heat[kJ/(kg•K)]0℃~100℃ |

0.50 |

|

Thermal Conductivity/[W/(m•K)] |

100℃: 16.3 |

|

500℃: - |

|

|

Coefficient of Thermal Expansion/(10-6/K) |

0℃~100℃: 15.7 |

|

0℃~500℃: - |

|

|

Electrical Resistivity/(Ω•mm2/m)20℃ |

0.69 |

|

Modulus of Elasticity(kN/mm2)20℃ |

197 |

Application:

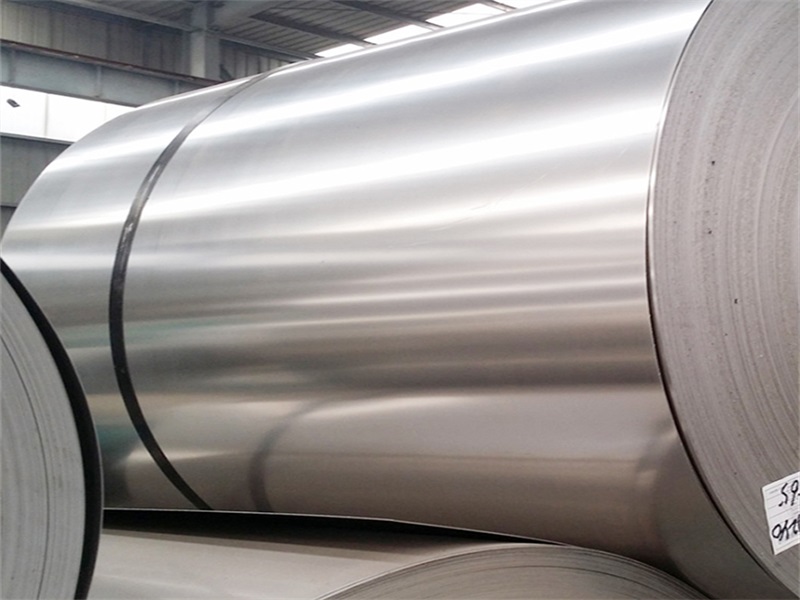

Cold rolled 201 stainless steel coil has the characteristics of acid resistance, alkali resistance, high density, no bubbles and no pinholes after polishing. 201 stainless steel coil is a high-quality material for making various watch cases and strap bottom covers. 201 stainless steel coiled tubes are mainly used for decorative tubes, industrial tubes and some shallow drawn products.

Stainless Steel Surface:

Stainless steel has a variety of surfaces, please contact us for confirmation.

|

Surface Finish |

Definition |

Application |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe. |

FAQ:

A:Sample can be for free,freight cost collect.

Q:What product information do I need to provide?

A:Steel grade/thickness/width/quantity,these will decide the price.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001,CE,SGS,BV and other certifications.

Q:How about the delivery time?

A:Regularly the delivery time around 10-15 days,customized one will inform the delivery time ahead.

Q:Does the product have quality inspection before loading?

A:All the products are strictly tested before packaging,also can inspect by third party inspection.

Q:How to pack the products?

A:Standard export package with waterproof film and wooden pallet.It can effectively protect products from corrosion.

Back to top

Back to top

Free quotation

Free quotation

Online Service

Online Service

Scheme customization

Scheme customization

Return to bottom

Return to bottom