Standards:

-

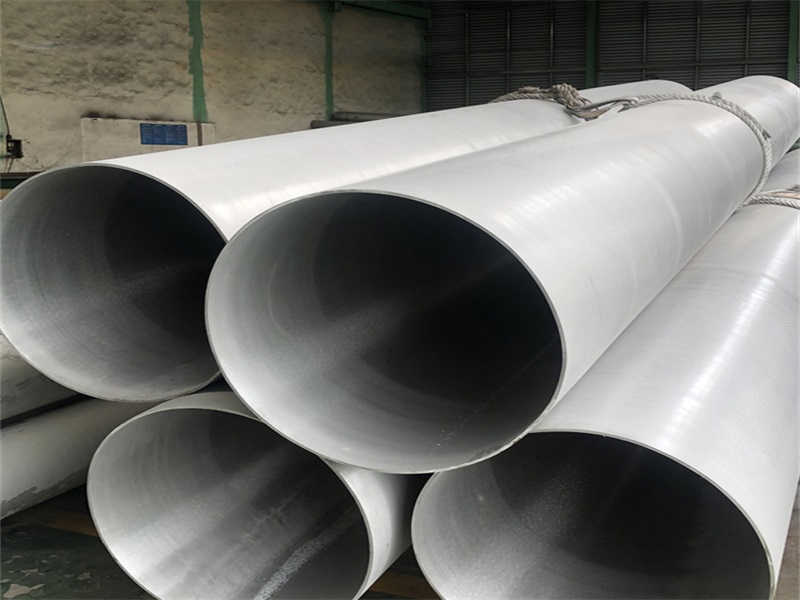

GB: 022Cr23Ni5Mo3N

-

ASTM: S32205/2205

Properties:

Chemical composition of duplex 2205 pipe:

-

C: ≤0.030

-

Si: ≤1.00

-

Mn: ≤2.00

-

P: ≤0.030

-

S: ≤0.020

-

Ni: 4.50~6.50

-

Cr:22.00~23.00

-

Mo: 3.00~3.50

-

N: 0.14~0.20

Mechanical properties of duplex 2205 stainless steel pipe:

-

Yield Strength RP0.2 / MPa:≥450

-

Tensile Strength Rm / MPa:≥655

-

Elongation after break A/%:≥25

-

Hardness value:HBW≤293;HRC≤31

Characteristic:

Because it contains 22%-23% chromium, 3%-3.5% molybdenum and 0.14%-0.20% nitrogen, the pitting and crevice corrosion resistance of duplex 2205 welded pipe has been greatly improved, and it is resistant to corrosion in most environments. Corrosion is much stronger than 316/316L steel.

2205 duplex stainless steel has good oxidation resistance and weldability at high temperature, and can be welded using welding techniques such as GTAW, GMAW, SMAW, SAW, FCW and PAW.

In terms of heat treatment, duplex 2205 pipe is mainly used for solution annealing and stress relief. During solution annealing, it should be annealed at a temperature of 1020°C-1100°C and cooled rapidly. Stress relief should be performed at temperatures below 1900°F.

Industry&Application:

Industry:

2205 stainless steel pipe is widely used in oil and gas industry, marine engineering, chemical industry, pulp and paper industry and other industries.

Application:

1. Fittings for oil and gas pipelines and heat exchangers.

2. Sewage treatment system.

3. Pulp and paper industry classifiers, bleaching equipment, storage and treatment systems.

4. Rotating shaft, press roller, blade, impeller, etc. in high strength and corrosion resistant environment.

5. Cargo boxes for ships or trucks

6. Food processing equipme

FAQ:

Q:Can you send samples?

A:Sample can be for free,freight cost collect.

Q:What product information do I need to provide?

A:Steel grade/thickness/width/quantity,these will decide the price.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001,CE,SGS,BV and other certifications.

Q:How about the delivery time?

A:Regularly the delvery time around 10-15 days,customized one will inform the delivery time ahead.

Q:Does the product have quality inspection before loading?

A:All the products are strictly tested before packaging,also can inspect by third party inspection.

Q:How to pack the products?

A:Standard export package with waterproof film and wooden pallet.It can effectively protect products from corrosion.

Back to top

Back to top

Free quotation

Free quotation

Online Service

Online Service

Scheme customization

Scheme customization

Return to bottom

Return to bottom