Standards:

|

Standards |

GB |

ASTM |

JIS |

ISO |

EN |

|

316 Stainless Steel |

06Cr17Ni12Mo2 |

S31600 |

SUS316 |

X5CrNiMo17-12-2 |

X5CrNiMo17-12-2 |

|

316L Stainless Steel |

022Cr17Ni12Mo2 |

S31603 |

SUS316L |

X2CrNiMo17-12-2 |

X2CrNiMo17-12-2 |

Properties:

Chemical properties:

|

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

N |

|

316 |

≤0.08 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

10.00~14.00 |

16.00~18.00 |

2.00~3.00 |

≤0.10 |

|

316L |

≤0.030 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

10.00~14.00 |

16.00~18.00 |

2.00~3.00 |

≤0.10 |

Mechancal properties:

|

Grade |

Yield Strength |

Tensile Strength |

Elongation after break |

Hardness value |

||

|

HBW |

HRB |

HV |

||||

|

316 |

≥205 |

≥515 |

≥40 |

≤217 |

≤95 |

≤220 |

|

316L |

≥180 |

≥485 |

≥40 |

≤217 |

≤95 |

≤220 |

Physical properties:

|

Grade |

316 Stainless Steel Sheet |

316L Stainless Steel Sheet |

|

Density/(kg/dm³)20℃ |

8.00 |

8.00 |

|

Melting Range/℃ |

1370~1397 |

- |

|

Specific Heat[kJ/(kg•K)]0℃~100℃ |

0.50 |

0.50 |

|

Thermal Conductivity/[W/(m•K)] |

100℃: 16.3 |

100℃: 16.3 |

|

500℃: 21.5 |

500℃: 21.5 |

|

|

Coefficient of Thermal Expansion/(10-6/K) |

0℃~100℃: 16.0 |

0℃~100℃: 16.0 |

|

0℃~500℃: 18.5 |

0℃~500℃: 18.5 |

|

|

Electrical Resistivity/(Ω•mm2/m)20℃ |

0.74 |

0.74 |

|

Modulus of Elasticity(kN/mm2)20℃ |

193 |

193 |

Application:

316 Steel:

Due to the addition of Mo element, 316 steel has greatly improved its corrosion resistance, atmospheric corrosion resistance and high temperature strength. In seawater and various other media, 316 stainless steel has better corrosion resistance than 304 steel.

The high temperature resistance of 316 steel can reach 1200-1300 degrees, it can be used under harsh conditions, and it is mainly used for pitting corrosion resistant materials.

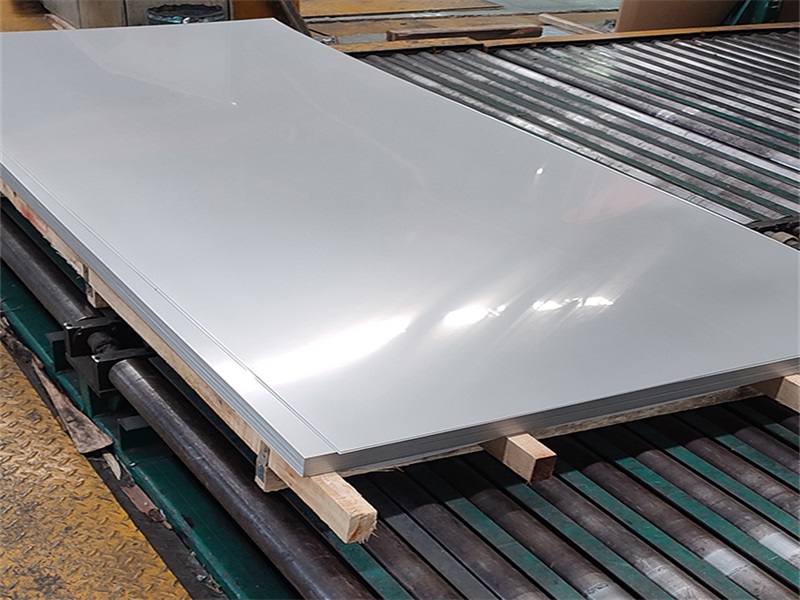

316 stainless steel plate has excellent work hardenability, excellent high temperature strength, and no magnetism in solid solution state.

The cold-rolled products of 316 stainless steel have good gloss and beauty. But compared with 304 steel, the price of 316 stainless steel sheet is higher.

316L Steel:

316L stainless steel sheet: ultra-low carbon steel for 316 stainless steel. 316L steel has good corrosion resistance to various inorganic acids, alkalis, and salts (such as sulfurous acid, sulfuric acid, phosphoric acid, acetic acid, formic acid, fluoride salts, sulfites, etc.).

Due to the low carbon content, 316L stainless steel has good welding performance and is suitable for multi-layer welding. Generally, heat treatment is not required after welding, and there is no tendency of knife-edge corrosion after welding.

316L stainless steel plate can be used to manufacture synthetic fiber, petrochemical, textile, chemical fertilizer, printing and dyeing and atomic energy and other industrial equipment, such as towers, tanks, containers, pipes, etc.

FAQ:

Q:Can you send samples?

A:Sample can be for free,freight cost collect.

Q:What product information do I need to provide?

A:Steel grade/thickness/width/quantity,these will decide the price.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001,CE,SGS,BV and other certifications.

Q:How about the delivery time?

A:Regularly the delivery time around 10-15 days,customized one will inform the delivery time ahead.

Q:Does the product have quality inspection before loading?

A:All the products are strictly tested before packaging,also can inspect by third party inspection.

Q:How to pack the products?

A:Standard export package with waterproof film and wooden pallet.It can effectively protect products from corrosion.

Back to top

Back to top

Free quotation

Free quotation

Online Service

Online Service

Scheme customization

Scheme customization

Return to bottom

Return to bottom